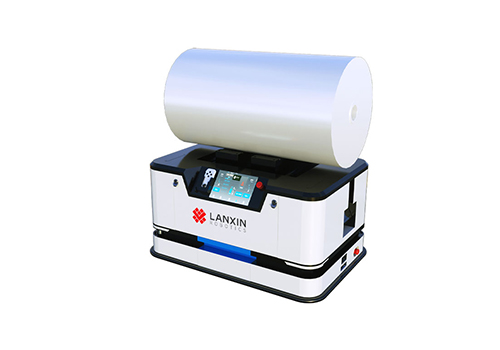

VMR-FR3300L

BATTERY INDUSTRY SOLUTION

Manual movement stirs dust, heavy coils pose hazards.

High-value goods need precise integration; no signage.

Workers, screens interfere; glass disrupts navigation.

Frequent line changeovers, varying distribution processes.

Exploring Stability

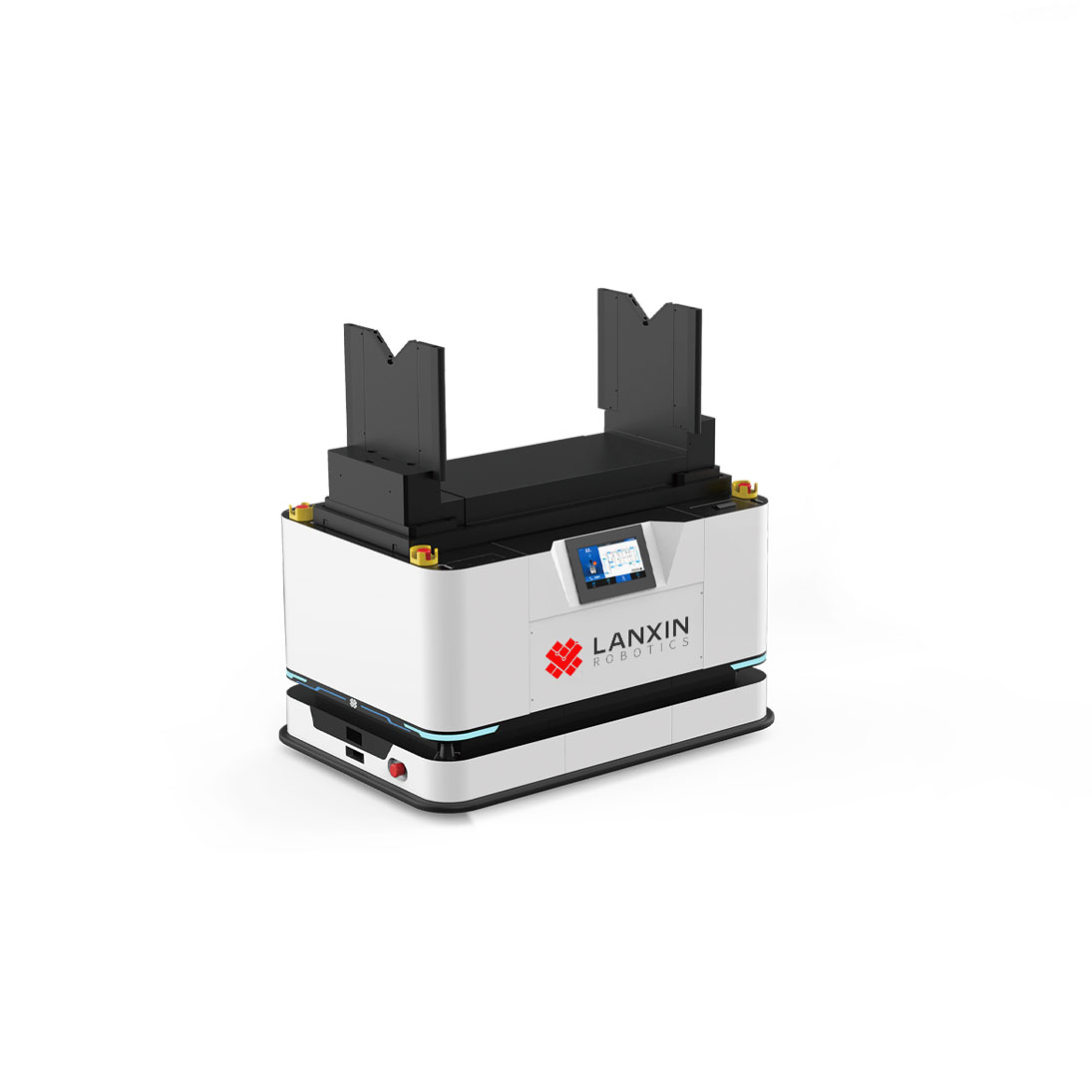

Integration with MBB soldering machine for loading/unloading: MES system initiates material offline/online tasks → AMS system sends tasks to Robot Control System (RCS) → Robots automatically dock with MBB soldering machine at task points to complete loading/unloading tasks before departing.

Integration with inline soldering machine for loading/unloading: MES system initiates material offline/online tasks → AMS system sends tasks to Robot Control System (RCS) → Robots automatically dock with inline soldering machine at task points to complete loading/unloading tasks before departing.

Ultra-high precision docking, capable of replacing manual labor for automatic loading and unloading of goods

LX-MRDVS® tech ensures stable positioning, navigation, and obstacle avoidance, even with glass interference.

RCS integrates with production management for scheduling, seamless tasks, connectivity, and real-time status.

Liberate Manpower

Triple-Production Line Logistics Efficiency

Enhance Corporate Brand

Liberate Manpower

≥100 daily shelf transport trips

Reduced work-related injury risk

Liberate Manpower

Triple Production Line Logistics Efficiency

Substantially Diminished-Workshop Airborne Dust

Contact Us

Lanxin Technology, 7-802,

China Artificial Intelligence Town,

No.1818-2 Wenyi West Road,

Hangzhou, Zhejiang, China

marketing@lanxincn.com

Popular Products

Cases

Industry