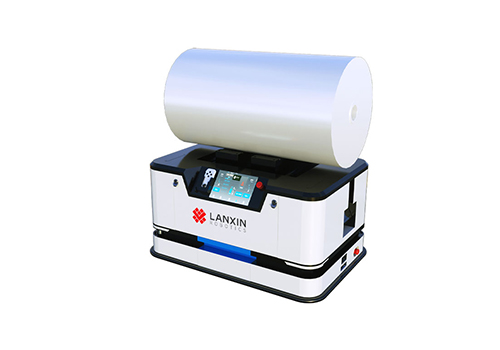

VMR-FR3300L

PHOTOVOLTAIC INDUSTRY SOLUTION

Manual movement stirs dust, heavy coils hazardous.

Workers, screens, and glass disrupt precise navigation.

Precise integration needed; no additional workshop signage.

Frequent line changeovers, varying distribution processes.

Exploring Stability

Warthog's onboard PC comes with the open-source Robot Operating System [ROS) preinstalled and configured.Rich documentation, demos and tutorials are provided,

along with a 3D simulation model for Gazebo to help you get started quickly and hassle-free.Warthog's onboard PC comes with the open-source Robot

LX-MRDVS® tech: visual positioning, navigation, obstacle avoidance, docking; stable even with glass interference.

RCS integrates with production management for scheduling, seamless tasks, connectivity, and real-time status visibility.

After algorithm optimization, the docking accuracy between the robot and the carding machine conveyor belt can reach ±1mm

Liberate Manpower

Triple-Production Line Logistics Efficiency

Enhance-Corporate Brand

Liberate Manpower

Daily Production Capacity

East China's largest 5G workshop

Liberate Manpower

Triple Line Logistics Efficiency

Traceable Raw Material Management

Contact Us

Lanxin Technology, 7-802,

China Artificial Intelligence Town,

No.1818-2 Wenyi West Road,

Hangzhou, Zhejiang, China

marketing@lanxincn.com

Popular Products

Cases

Industry

.png)