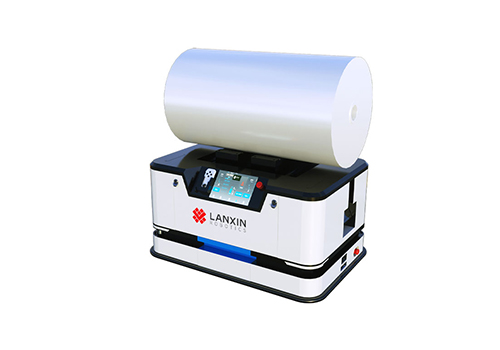

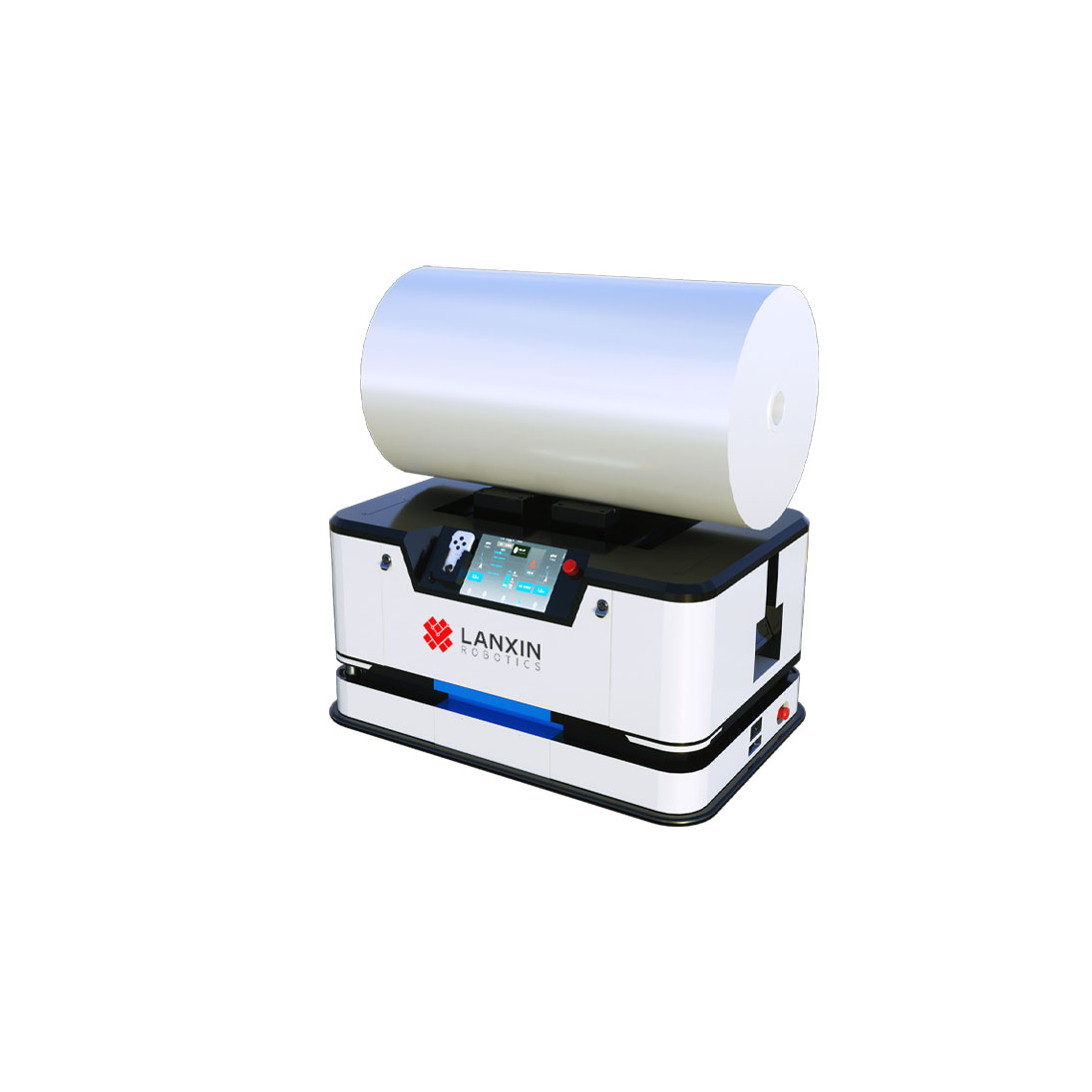

VMR-FR3300L

PACKAGING & GENERAL SOLUTION

Heavy coils need precise multi-process integration.

Risky: Shared pathways; high robot safety needed.

Narrow passages restrict machinery, increase collision risks.

Frequent cargo moves make laser navigation unreliable.

Exploring Security

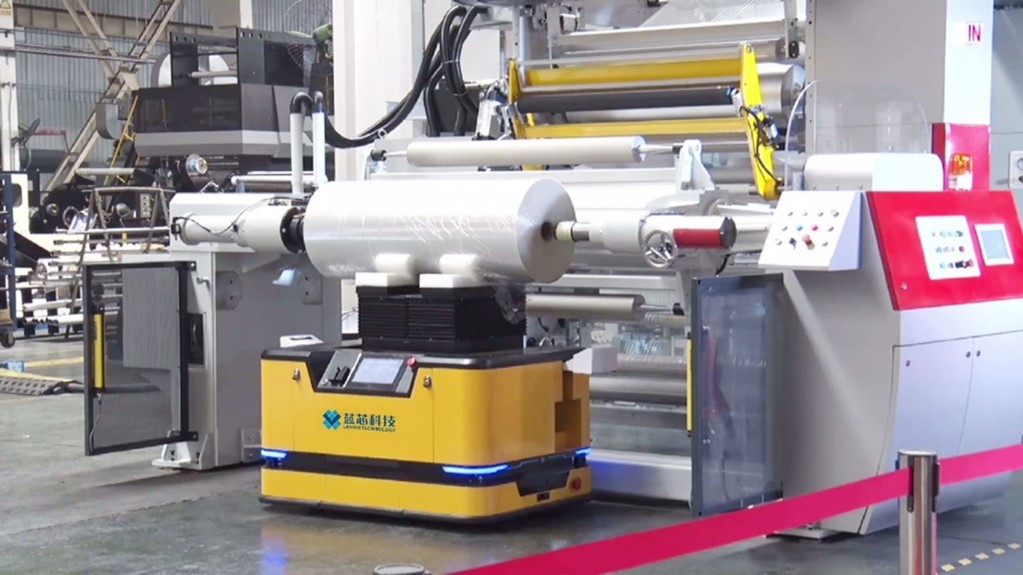

Workers call the robot for loading via electronic devices. The Robot Control System automatically assigns tasks to the robot, which then proceeds to the coil buffer rack, docks automatically, and picks up the coil to deliver it to the printing machine station. Once loading is complete, the robot autonomously departs. Additionally, unmanned forklifts are used for inbound and outbound transportation of finished products.

While reducing the hazards associated with roll material, uninterrupted production is achieved

LX-MRDVS® tech: visual positioning, navigation, obstacle avoidance, and docking. Stable even with glass interference.

RCS integrates with production management for scheduling, tasks, connectivity, and real-time status.

7*24H Uninterrupted Production

Liberate Manpowerics Efficiency

Supply Delay Rate

Liberate Manpower

Double-Production Line Logistics Efficiency

Significantly Reduced - Risk of Work-related Injuries

Double Logistics Efficiency

Fully Traceable Process

Confidential No Human Contact

Contact Us

Lanxin Technology, 7-802,

China Artificial Intelligence Town,

No.1818-2 Wenyi West Road,

Hangzhou, Zhejiang, China

marketing@lanxincn.com

Popular Products

Cases

Industry

.jpg)