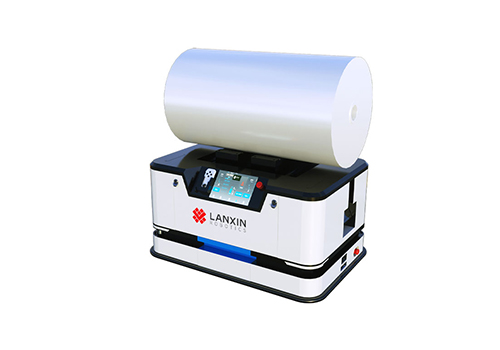

VMR-FR3300L

360도 완벽한 커버리지와 3D 장애물 회피 기술을 채택하여 바쁜 환경에서의 안전한 운영을 보장합니다.

실제 SLAM 자연 탐색 시스템을 사용하여 추가 장비 배치 없이 즉시 사용할 수 있으며, 운영 편리성을 크게 향상시킵니다.

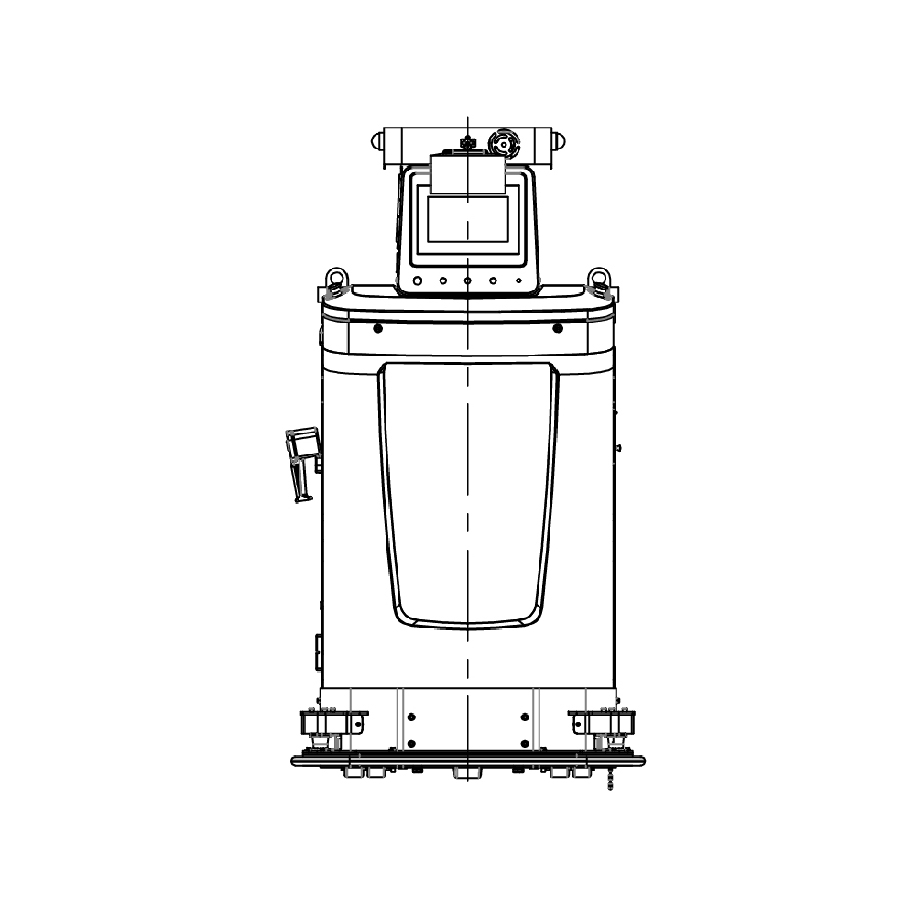

전면 보기

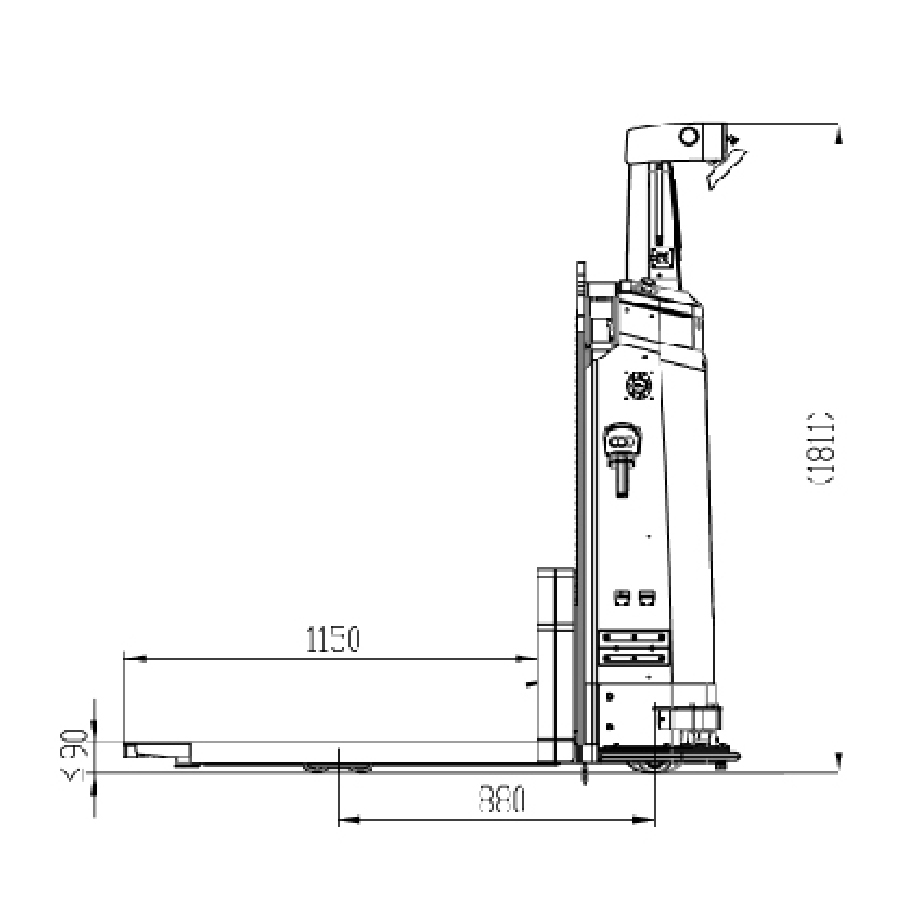

측면 보기

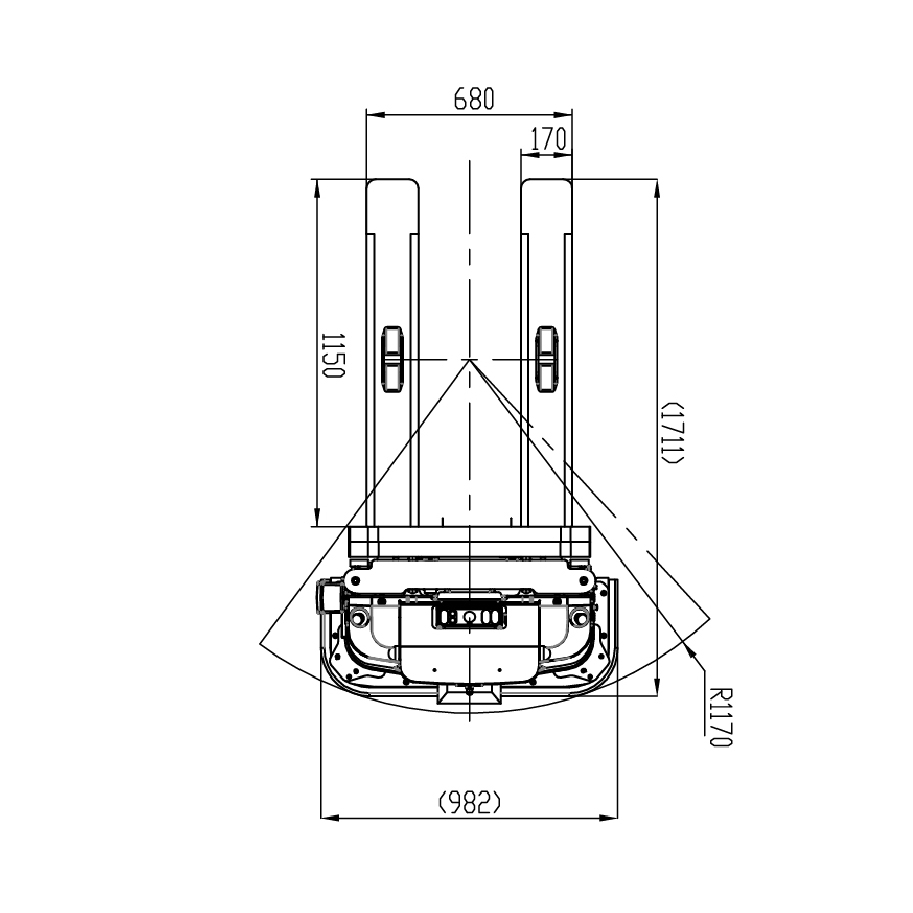

위로 보기

1400

적재 용량(kg)

1.5

최대 속도(m/s)

2350

회전 지름(mm)

3500

제고 높이(mm)

기본 사항

치수(L*W*H)

1720 mm * 990 mm * 1820 mm

네트 웨이트

1050 kg

회전 지름

φ2350 mm

용량

정격荷重

1400 kg(Max)

들어올림 높이

1600 mm(3500 mm Max)

부하 중심

600 mm

포크 크기 (LWH)

1150 mm * 170 mm * 60 mm (x2)

포크 바깥 폭

680 미터(mm, 표준)

안전

보호 범위

360° 커버리지

보호 조치

세단계 보호: 감속, 점진 정지, 긴급 정지

레이저 장애물 회피

3개의 전후 레이저 센서로 360° 커버리지

안전 에지

전면 반 포장 보호

긴급 정지 버튼

로봇 주변에서 한 손의 도달 범위

음성 및 시각 경보

조명 표시 + 음성 알림

비전 장애물 회피

선택사항

동작

주행 모드

단일 스티어링 휠

탐색 모드

자연 탐색, 비전 / 레이저 SLAM

주행 방향

전진, 후진, 회전, 좌/우 전환

속도

0~1.5 미터/초

정지 위치 정확도

±10 밀리미터

정지 각도 정확도

±1 도

배터리

배터리 유형

LFP (리튬 이온 페로스카이드 배터리)

배터리 용량

24볼트 150앰페어어

배터리 수명

6-8시간

충전 방법

자동 / 수동 충전

충전 시간

3시간 이하

수명 주기

2000회 충전循環

HMI

LCD 패널

지원

조명 표시

로봇 상태, 고장 알람, 배터리 전력 등

음성 알림

터닝, 경고, 음악 재생 등

버튼 조작

긴급 정지 버튼, 전원 스위치 버튼, 작동 버튼

수동 원격 조종기

지원

확장 인터페이스

RJ45(100MB)

환경

적용 시나리오

실내

작동 온도

0~40℃

습도

10~90%RH, 응축 없음

지면 기울기

무하중 시 ≤ 5% / 전체하중 시 3%

네트워크 통신

와이파이 IEEE802.11 a/b/g/n/ac/ax, 5G(선택사항)

90° 팔레트 픽업용 통로 폭

2340 mm (팔레트: 12001200 mm)

Contact Us

Lanxin Technology, 7-802,

China Artificial Intelligence Town,

No.1818-2 Wenyi West Road,

Hangzhou, Zhejiang, China

marketing@lanxincn.com

Popular Products

Cases

MRDVS®-3D visual perception

Notice: Undefined variable: slides_1 in /www/wwwroot/lanxinrobotics.com/proInfo.php on line 650

.png)