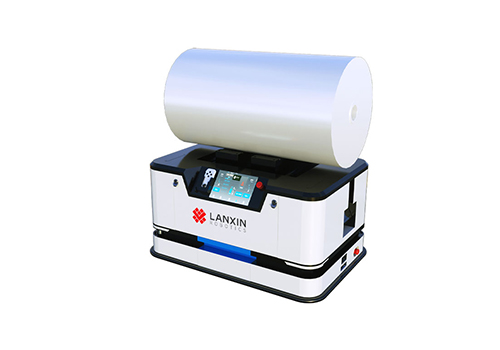

VMR-FR3300L

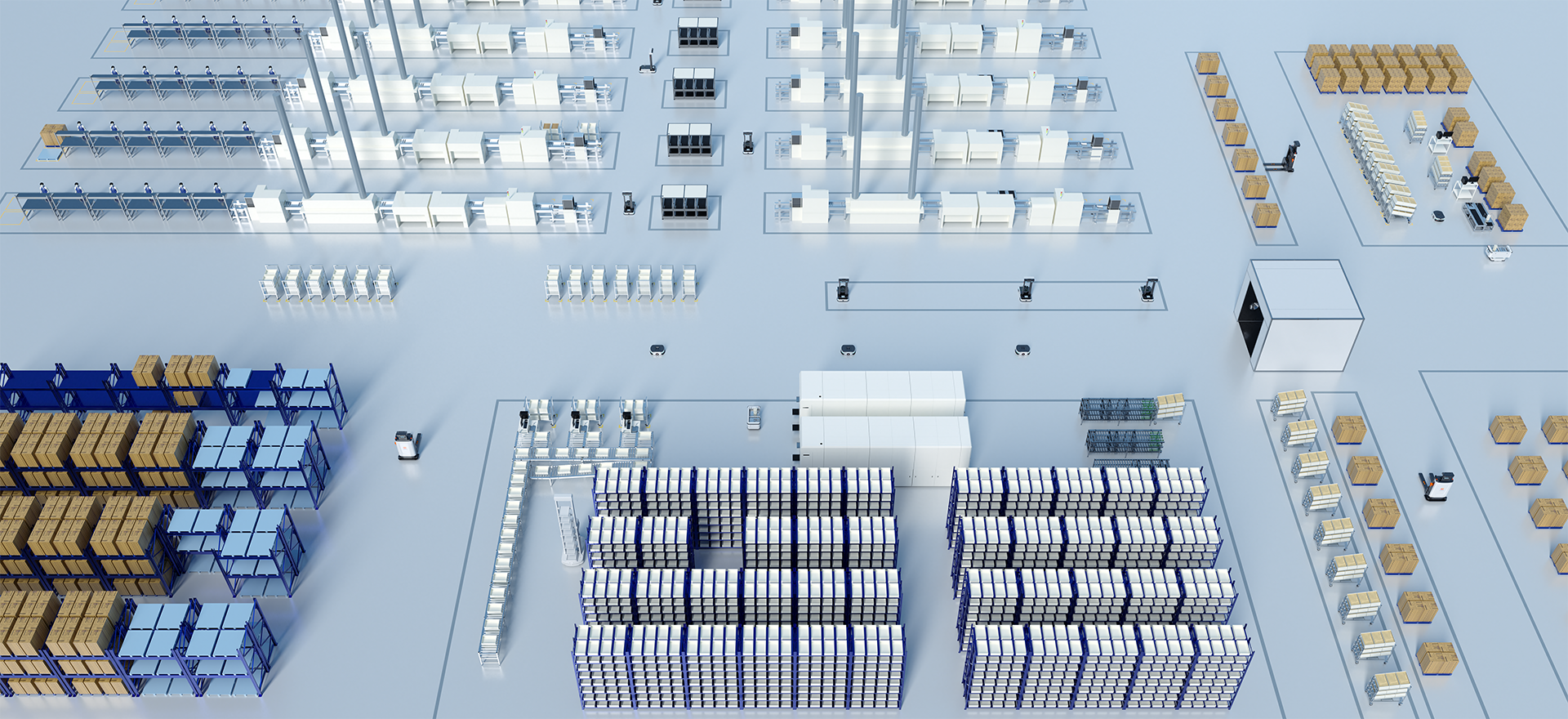

ELECTRICAL & ELECTRONICS INDUSTRY SOLUTION

Risky: Shared pathways; robots need high safety.

High-value goods require precise multi-process integration.

Early-built factory challenging to upgrade environment.

The laser-guided unsuitable: frequent movement, changes.

Exploring Innovation

1. Using AGV + racks enables timely recycling of raw materials and packaging waste on the production line.

2. Employing SMT robots allows for automatic handling and loading/unloading of PCB trays.

3. Utilizing mobile compound robots facilitates automatic loading and unloading of semiconductor wafer boxes.

4. Implementing unmanned forklifts enables the handling of entire pallets for inbound and outbound logistics.

LX-MRDVS® enables loading and unloading robots to navigate naturally without markers, ensuring stable localization despite ground environment interference using integrated positioning.

RCS connects with production management, enabling scheduling, task transitions, equipment connectivity, and real-time robot status visibility within the enterprise's system.

LX-MRDVS® tech enables stable positioning amidst glass wall interference, with integrated cameras enhancing safety by detecting obstacles and operators.

Liberate Manpower

Production Capacity Increase

Payback Period(years)

Liberate Manpower

Feed Delay Rate Down to

5S Standard Significantly Improved

Liberate Manpower

Feeding and Recycling Efficiency

Information Management

Contact Us

Lanxin Technology, 7-802,

China Artificial Intelligence Town,

No.1818-2 Wenyi West Road,

Hangzhou, Zhejiang, China

marketing@lanxincn.com

Popular Products

Cases

Industry

.jpg)