Packaging

Handle coil automatic handling & loading and unloading, auxiliary material distribution, finished product warehousing and storage.

Solution / Packaging

Challenges

Extreme precision

Mixed traffic

Limited space

Unstable environments

Solution

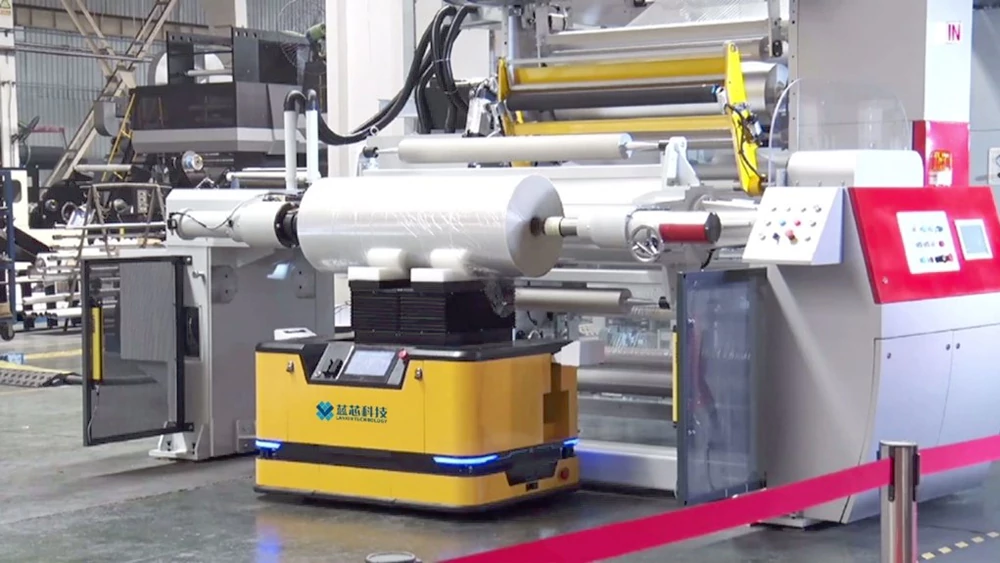

Workers call the robot for loading via electronic devices. RCS automatically assigns tasks to the robot, which then proceeds to the coil buffer rack, docks automatically, and picks up the coil to deliver it to the printing machine station. Once loading is complete, the robot autonomously departs. Additionally, unmanned forklifts are used for inbound and outbound transportation of finished products.

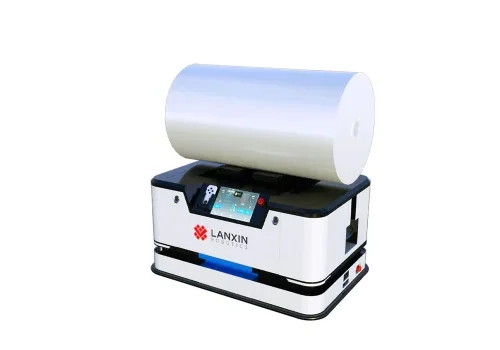

Products

Why It Works

While reducing the hazards associated with roll material, uninterrupted production is achieved.

LX-MRDVS® tech: visual positioning, navigation, obstacle avoidance, and docking. Stable even with glass interference.

RCS integrates with production management for scheduling, tasks, connectivity, and real-time status.

80%+ reduction in manual handling costs.

“We achieved intelligent production from raw material distribution to warehousing and established a logistics information system. Choosing Lanxin Technology, we introduced Lanxin AMR robots and intelligent logistics solutions after joint development.” – Manager from YUTO China

Robots Handle High-risk Goods Instead

The company aims to automate loading and unloading of printing machines and unmanned coil transportation to reduce labor, cut costs, and boost efficiency. Manual handling of heavy coils is labor-intensive, inefficient, and risky. This initiative addresses labor shortages and high turnover rates faced by end enterprises.

Passports Delivered by Roller Robots at Public Security Bureau

Before robots, manual labor handled passport circulation, reducing efficiency. Now, robots retrieve trays of applicant information and blank passports, delivering them for encoding, printing, laminating, and inspection, enhancing production efficiency.